Semisils is located in Liuying, Tainan, primarily recycling silicon slurry waste from semiconductor processes and solar panels. This waste material is processed and transformed into epoxy and calcium silicate boards, used in the production of products like basketballs and safety shoes, contributing to a silicon-based circular economy. During the recycling process, approximately 98% pure hydrogen gas is produced. To avoid wasting this byproduct, Semisils sought assistance from AMPOWER to plan a hydrogen power generation solution.

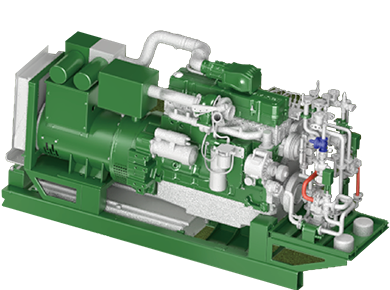

AMPOWER provided Semisils with a 2G Energy AG 115kW hydrogen generator. Unlike hydrogen fuel cells that require highly purified hydrogen (99.9999%), this engine generator allows the use of hydrogen with impurities, making it suitable as a fuel even if other gasses are present. Furthermore, while typical hydrogen fuel cells take over 4 hours to reach full capacity, the engine generator can be fully loaded in just 2 minutes.

In addition, the hydrogen generator installed by AMPOWER for Semisils has combined heat and power (CHP) capabilities. The excess heat generated can be directly utilized for processes such as water heating, steam production, or kerosene heating. It can also be coupled with an adsorption chiller to expand its applications to air conditioning or refrigeration. This generator helps reduce Semisils’ contracted capacity, serves as an emergency power supply system, lowers carbon emissions, and enhances energy efficiency.

In conclusion, Semisils’ successful utilization of hydrogen from the manufacturing process for power generation has earned them a renewable energy certificate, representing a significant achievement in AMPOWER’s portfolio in the field of renewable energy.